In-situ High Temp System

Overview

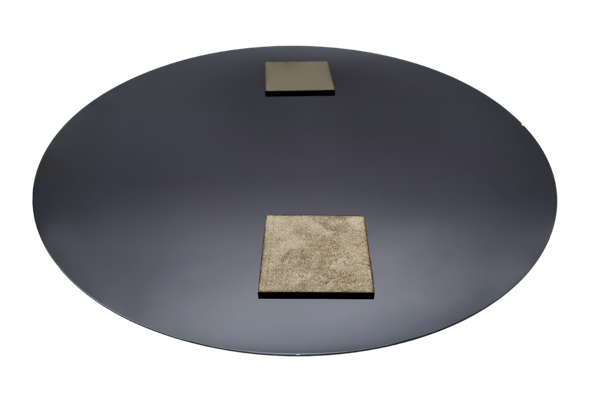

In-situHigh Temp System is designed to optimize and monitor advanced film processes(FEOL and BEOL ALD, CVD and PVD) and other elevated temperature processes. In-situ High Temp System wafer measures process tool thermal uniformity, providing a complete picture of temporal and spatial temperature data collected in real-time under actual production process conditions.By revealing thermal variations in applications such as plasma environments that can affect process windows and patterning performance, the system helps IC manufacturers optimize the integration of new materials, transistor technologies and complex patterning techniques.

Features

a.High precision, flexible application, fast sampling speed;

b.Acquisition frequency up to 4Hz, temperature accuracy ±0.2° C;

c.Point-to-point wireless communication.

Sizes | Wafer diameter 300mm(12 inches)±0.2mm Above the wafer is less than 6mm |

Power Source | Battery |

Operating Range | 0℃~850℃ |

Accuracy | ±0.2℃ |

Repeated Measurement Accuracy | <0.1℃ |

Number of sensors | 21 |

Sampling Frequency | max.4Hz |

Sensor Response Time | ≤1s |

Communications | WiFi |

Continuous Use Life | 0℃~850℃,7minutes 0℃~650℃,15minutes |

Substrate Material | Si |

Applications | Process development, Process qualification, Process tool monitoring, Process tool qualification, Process tool matching, CVD, PVD, ALD, Track, Stripper, Dry Etch |

Warranty | 1year |

Delivering Growth – in Asia and Beyond.

Hu ICP Bei No. 2023002235

Hu ICP Bei No. 2023002235